Level Measurement

Precise distance measurement with radar technology

The industrial environment is inconceivable any more without sensors. They take on tasks for us that we would perform with great difficulty or imprecisely. Like a kind of additional sensory organ, they enable better interaction between humans, machines, and the environment. The technology facilitates our work, optimises processes, or provides us with additional safety in the modern working world. In light of trends such as automation and autonomisation in the industrial sector, it is becoming apparent how important sensors and their measurements will prove to be in the future.

A traditional application area is distance measurement.

For this purpose, the sensors continuously determine the distance to an object’s surface. Just distance information alone already enables a variety of tasks to be taken over by technology in order to help support us – from level monitoring to protecting against collisions. The police are also quite familiar with distance measurement. The measuring technology’s precision & reliability are important criteria when opting for a solution. This is particularly the case when extensive planning (material management) or protective measures (safe distance) rely on the measurement data collected. As a positioning method, radar is ideally suited for determining distances. However, this sensor technology boasts further properties that it well-suited for use in distance measurement for industry.

At a glance

Radar utilises electromagnetic waves to determine an object’s position. For this purpose, the equipment measures the distance and – depending on the modulation – also further object data. The sensor’s antenna emits radar waves that are reflected by an object’s surface. The reflection changes the transmitted signal and thus provides the necessary data for positioning. The measuring method is non-contact in nature. Radar enables continuous monitoring of distances – i.e. the equipment detects minute changes in real time.

Among other things, the following parameters can be determined using a specially configured distance radar:

distances between the sensor (antenna) and an object’s surface

signal strength (RCS)

static objects or very slow movements

Their advantages

contactless measurement – no contact with the object necessary

continuous & always up to date – data in real time and fast response in the event of changes in distance

precise & reliable – millimetre-precise measurements & also only minor deviations over distance

weather-resistant – suitable for indoor & outdoor use

temperature-resistant – Extreme heat or cold is not a problem.

compact – for easy installation even in small spaces

passes through plastics – can be installed behind covers

maintenance-free – Dirt, noise, or vibrations do not impair functionality.

versatile – Detects the object’s surface no matter what its composition (liquids, granules, powders, etc.)

Touchfree distance measurement with radar

Multiple measuring points vs single-target measurement

Depending on the application and the object’s material, InnoSenT offers two different measurement variants, which differ in terms of the number of targets detected. Radar experts refer to multi-target and single-target detection.

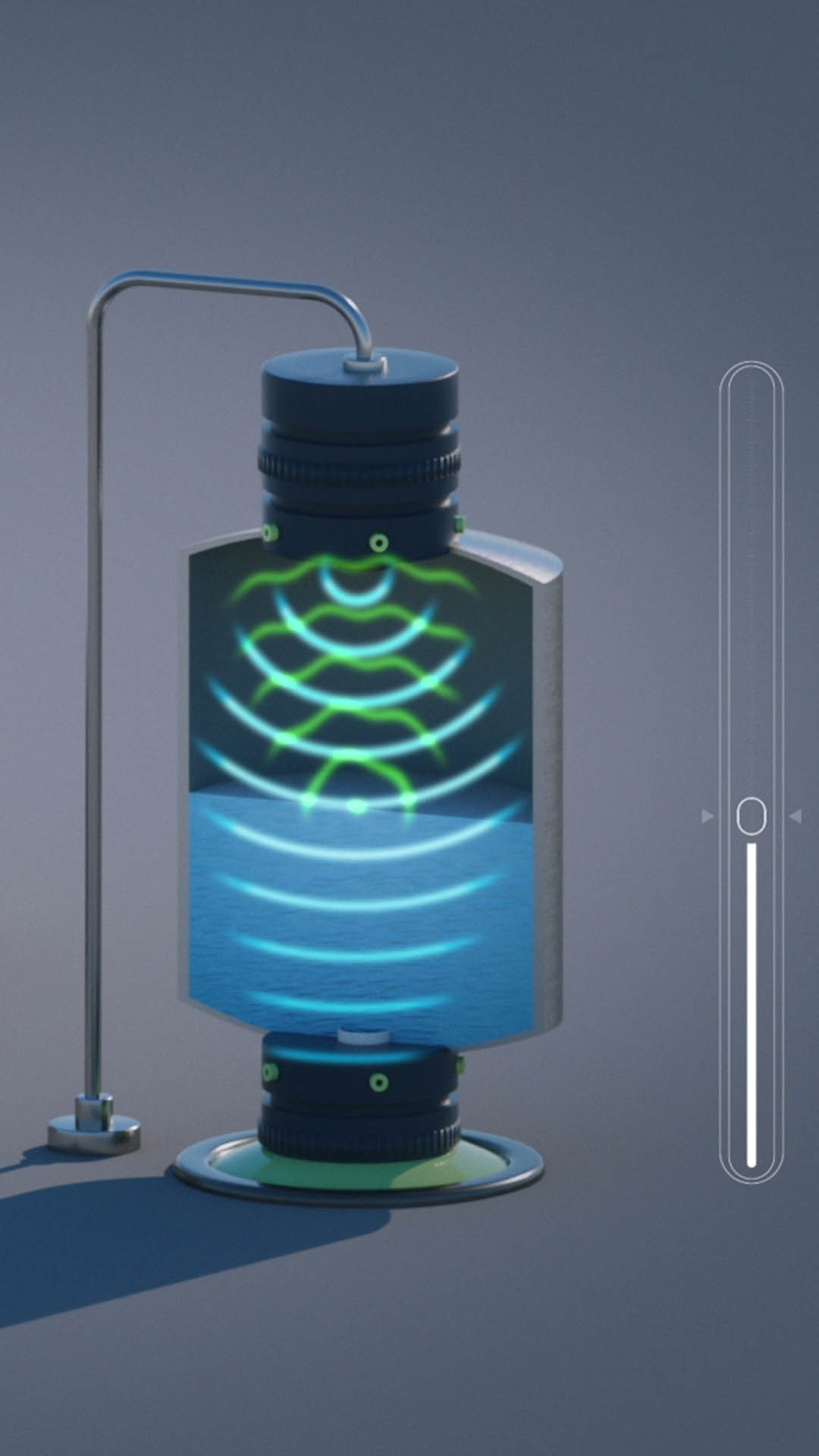

Single-Target-Mode

Single-target measurement proves advantageous when the system is installed in complex measuring environments, as interfering factors are hidden. A narrow, focused radar beam measures the distance between the sensor and object at a particular point. Unevenness and interfering factors do not distort the measurement result. The single-target mode also achieves particularly fast results thanks to its focusing.

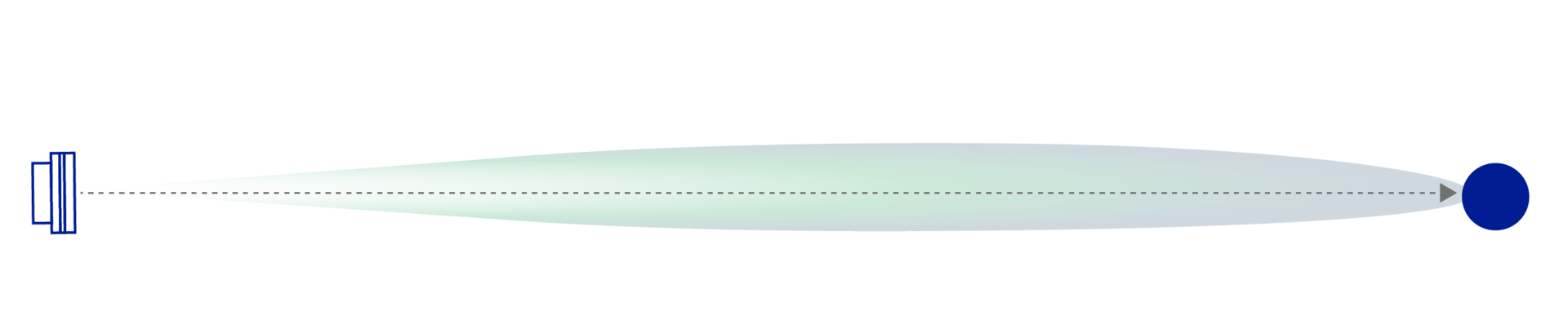

Multi-Target-Mode

In multi-target mode, the radar records multiple targets within the detection range in order to attain a compiled data result or to measure different distances or heights if required.

Level Measurement

Quality, process optimisation, and efficiency gains in production, storage, and materials management are becoming increasingly important. In order to plan successfully, it is necessary to know the exact stock or the current level. This helps prevent overflowing or shortages through a warning function, for example.

Fill level measurement

Radar enables fill levels to be determined precisely and reliably. Companies rely on this measurement technology particularly when dealing with silos, tanks, or large storage containers whose accessibility to employees is limited or that are completely sealed off. They receive information about the amount of content based on the distance change in an automated and digital manner. Fill level measurement is used, for example, in sectors such as food production, chemicals, building materials, raw materials, and energy generation.

Level monitoring

Radar detects not only solid filling materials, but also liquids. Even slow-flowing and slow-moving materials are no problem – this enables radar to be used in mobile tanks, pipes, or ducts. The technology can determine the level of a flow with millimetre precision by means of distance measurement. Depending on how the sensor solution is equipped, the flow rate may also be able to be calculated.

Distance Measurement

The distance information also enables object’s to be measured. For this purpose, the sensor is in motion. For example, it might be mounted on a rail or attached to a transport vehicle. In addition, the target to be detected may have different characteristics. The information regarding the distance to the sensor enables the contours of an object to be made out or a device to be precisely oriented.

Height determination

The sensor looks at an object from the top to bottom in order to determine the height using the reference data regarding the ground and the distance information. A typical example is the lift height measurement of a forklift or the alignment of agricultural machinery with the height of the crops to be harvested in the field.

Contour measurement

If the radar is on a moving base, the sensor also detects slight deviations in the object’s surface. This allows the contour to be measured and displayed. The radar maps the smallest changes in height based on the distance information. For example, this enables large objects to be detected from a long distance.

Product Highlights

InnoSenT´s Distance-Radarsensors

Distanz Radarsensoren von InnoSenT

Radarsystem

iSYS-6030

The 60 GHz radar system has a 40 metre range and is optimally adapted to applications for fill level detection and collision protection. It provides precise & reliable measurement results thanks to its highly focused radar beam and an aperture angle of 6° (in azimuth and elevation).

- millimetre-precise distance measurement

- measures signal strength (RCS)

- low power consumption and standby mode

- fast update rate

- filtering of the measurement results possible

- has a single-target and multi-target mode

four configurable outputs for trigger functions

Radarsystem

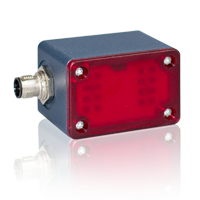

iSYS-4004

With the iSYS-4004, InnoSenT also offers a radar solution for distance measurement in the 24 GHz frequency range. The FMCW radar detects stationary and moving objects within a range of up to 35 metres. Thanks to MMIC technology, it provides stable and accurate measurement results.

- determines the distance to one or more objects in the detection area

- detects the presence of static and moving objects

- already integrated in robust metal housing

- has three configurable outputs (triggers)

- selectable bandwidth between 250 MHz (EU) with ±3 cm measurement accuracy and 100 MHz (US & UK) with ±7.5 cm measurement accuracy